Browse Challenging Terrain with Confidence: Komatsu Undercarriage Parts Choice Guide

Browse Challenging Terrain with Confidence: Komatsu Undercarriage Parts Choice Guide

Blog Article

Reliable Solutions: Undercarriage Components for Heavy Machinery

When it involves hefty machinery, the undercarriage is a vital part that frequently determines the total effectiveness and performance of the devices. Quality undercarriage components play a substantial duty in guaranteeing the smooth procedure and longevity of hefty equipment. From excavators to dozers, each tool counts greatly on its undercarriage to stand up to hard working problems. Nevertheless, deterioration are inevitable, resulting in possible problems that can prevent performance and increase maintenance prices (komatsu undercarriage parts). In this discussion, we will explore the value of spending in excellent undercarriage parts, usual wear challenges encountered by heavy machinery operators, the benefits of timely replacements, standards for selecting reliable vendors, and important maintenance tips to extend the lifespan of undercarriage elements.

Significance of High Quality Undercarriage Parts

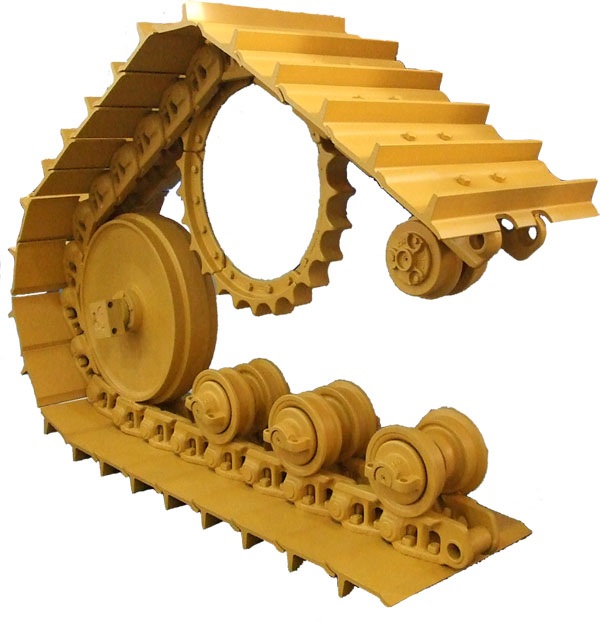

Quality undercarriage components are crucial elements in guaranteeing the toughness and performance of heavy equipment. The undercarriage of devices such as excavators, excavators, and track loaders plays a vital duty in sustaining the equipment's weight, offering stability on numerous surfaces, and taking in the impact of unequal surface areas. By investing in top quality undercarriage components, drivers can significantly extend the life-span of their machinery and reduce the risk of unexpected malfunctions.

One key advantage of using top quality undercarriage components is the enhancement of general device performance. Resilient tracks, idlers, gears, and rollers reduce rubbing and make sure smoother motion, ultimately leading to increased efficiency and performance on job sites. Trustworthy undercarriage elements reduce downtime for upkeep and repair services, permitting drivers to optimize their operational hours and task deadlines.

Typical Undercarriage Put On Concerns

Advantages of Timely Replacement

One trick benefit of timely undercarriage part replacement is increased device uptime. By replacing used components before they fall short, the danger of unanticipated break downs is reduced, reducing downtime for fixings and maintenance. This proactive strategy not just keeps the hefty machinery functional but also protects against potential damage to other parts that can result from a falling her explanation short undercarriage.

Furthermore, changing undercarriage parts without delay can enhance total productivity. Spending in timely undercarriage part replacement is a positive method that pays off in terms of enhanced performance and lowered functional costs.

Picking the Right Undercarriage Distributor

Selecting the appropriate undercarriage provider is a vital decision that dramatically influences the performance and upkeep of hefty equipment. When choosing a provider for undercarriage components, several elements have to be thought about to guarantee optimum performance and cost-effectiveness. It is necessary to evaluate the distributor's online reputation and experience in the sector. A trusted vendor with years of experience is most likely to provide premium components and trustworthy service. In addition, think about the variety of items used by the vendor. A vendor that uses a broad selection of undercarriage components for numerous heavy equipment brand names and designs can be advantageous as it gives more alternatives to meet details needs.

Moreover, reviewing the distributor's client solution and support is essential. A provider that supplies superb customer support, fast response times, and technical aid can assist lessen downtime and make certain smooth procedures. Cost is likewise a significant factor to consider; nevertheless, it ought to not be the sole determinant. When selecting the ideal undercarriage supplier for hefty machinery, stabilizing high quality, integrity, and cost-effectiveness is key. By thoroughly reviewing these factors, you can choose a supplier that meets your requirements and contributes to the efficient performance and upkeep of your heavy equipment.

Maintenance Tips for Extended Life Expectancy

To make certain an extensive lifespan for hefty machinery undercarriage parts, executing an aggressive upkeep routine is vital. Regularly inspecting undercarriage components such as track chains, idlers, rollers, and sprockets for damage is crucial. Any kind of indicators of damage or too much wear ought to be quickly addressed to avoid additional damage and possible failures. In addition, maintaining the undercarriage tidy from dust, particles, and corrosive materials can considerably extend its life expectancy. Greasing moving parts according to supplier recommendations aids minimize rubbing and avoid premature wear. Keeping an eye on track stress check that and alignment is also essential to stop unequal wear on the undercarriage components. Investing in top quality undercarriage components from reputable vendors is just as essential go to my site for ensuring long life. By adhering to these maintenance ideas carefully, heavy equipment owners can enhance the efficiency and toughness of their undercarriage components, eventually decreasing downtime and operational costs.

Verdict

To conclude, top quality undercarriage parts are necessary for the effective operation of hefty machinery. Prompt replacement of worn components can protect against expensive downtime and keep ideal performance. Picking a reliable vendor and adhering to correct upkeep methods are essential to ensuring the extended lifespan of undercarriage parts. By dealing with common wear problems and buying high-grade parts, heavy machinery operators can maximize performance and decrease maintenance prices.

Extreme wear and tear on undercarriage parts of heavy machinery can lead to significant functional obstacles and raised maintenance costs. Regular inspections, proper maintenance, and prompt substitutes of used undercarriage components are vital to minimize these typical wear issues and guarantee the optimum performance of heavy equipment.

A supplier that provides a large selection of undercarriage components for various heavy machinery brands and designs can be advantageous as it offers extra alternatives to satisfy specific needs.

By following these upkeep ideas vigilantly, heavy machinery proprietors can optimize the efficiency and toughness of their undercarriage parts, ultimately minimizing downtime and functional expenses.

Report this page